|

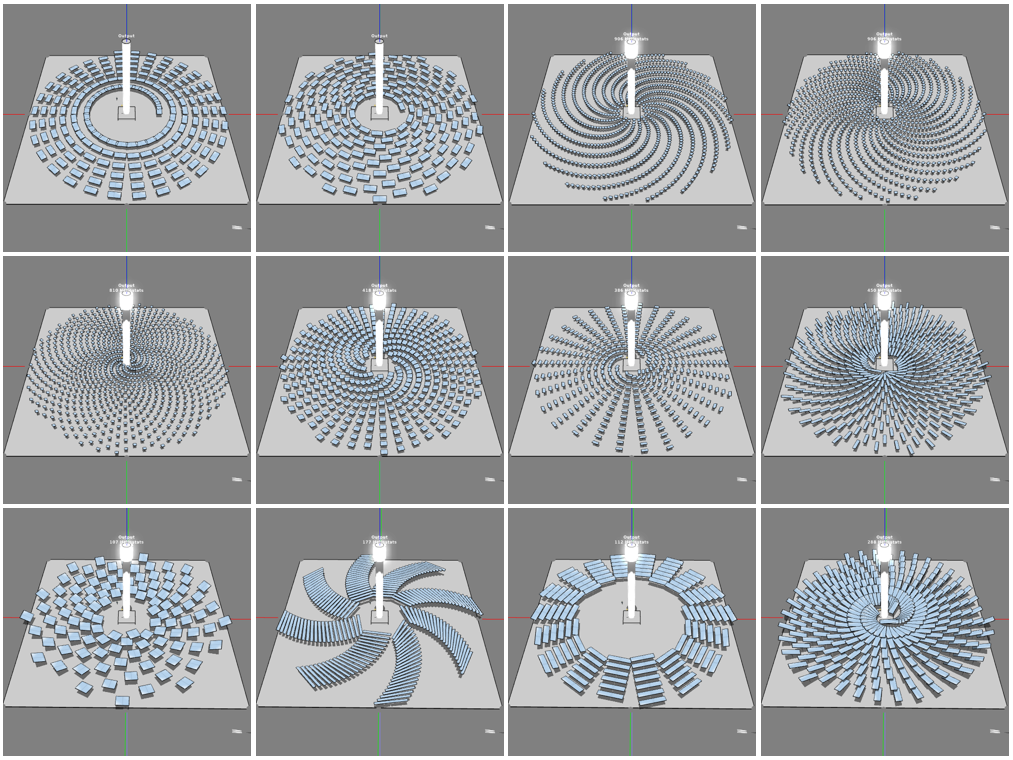

| Fig. 1: Integrated design and simulation in Energy3D |

Some researchers, however, cautioned that using CAD tools in engineering practices and education could result in negative side effects, such as circumscribed thinking, premature fixation, and bounded ideation, which undermine design creativity and erode existing culture. To put the issues in a perspective, these downsides probably exist in any type of tools — computer-based or not — to various extents, as all tools inevitably have their own strengths and weaknesses. As a matter of fact, the development history of CAD tools can be viewed as a progress of breaking through their own limitations and engendering new possibilities that could not have been achieved before. To do justice to the innovative community of CAD developers and researchers at large, we believe it is time to revisit these issues and investigate how modern CAD tools can address previously identified weaknesses. This was the reason that motivated us to publish a paper in Computer Applications in Engineering Education to expound our points of view and supporting them with research findings.

|

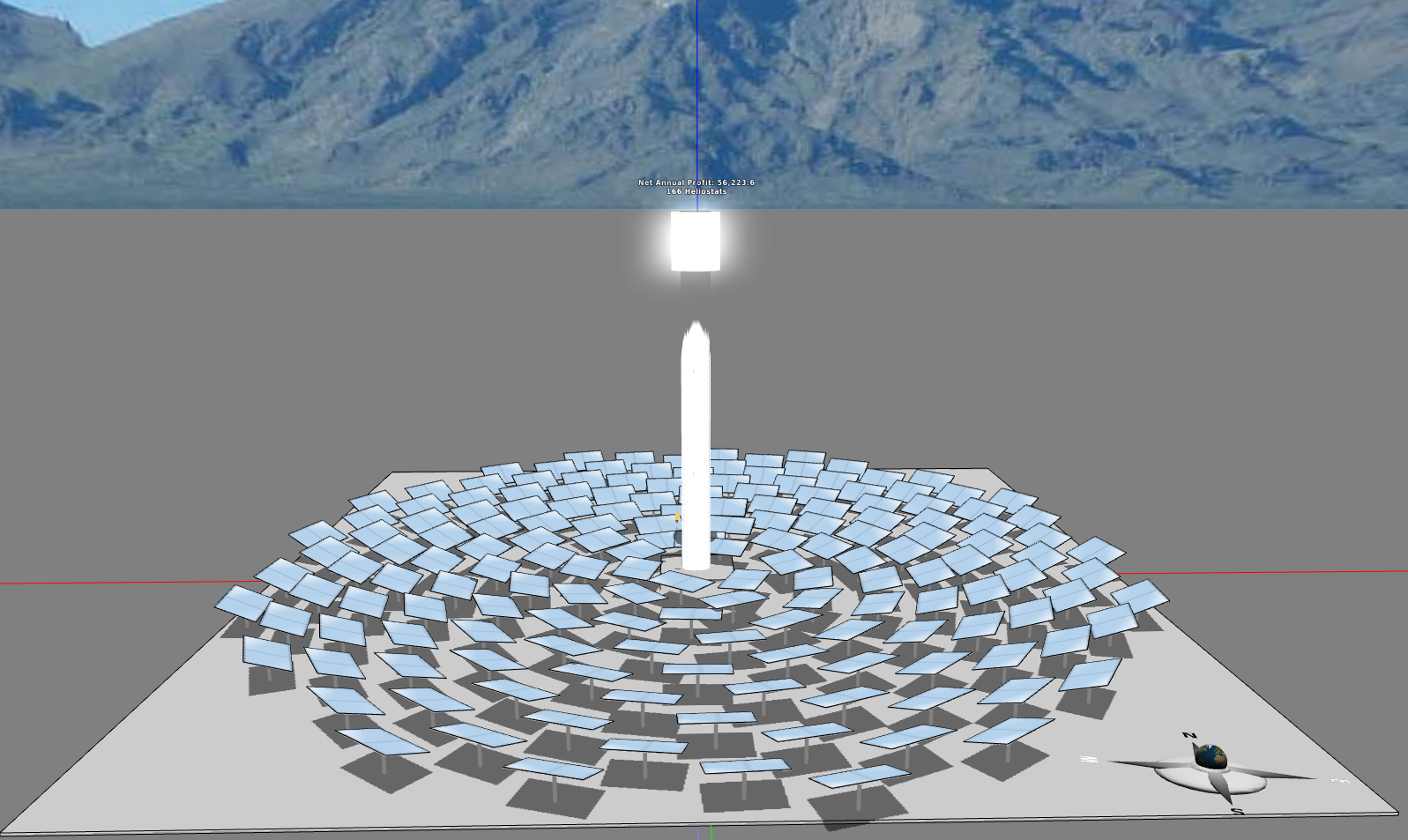

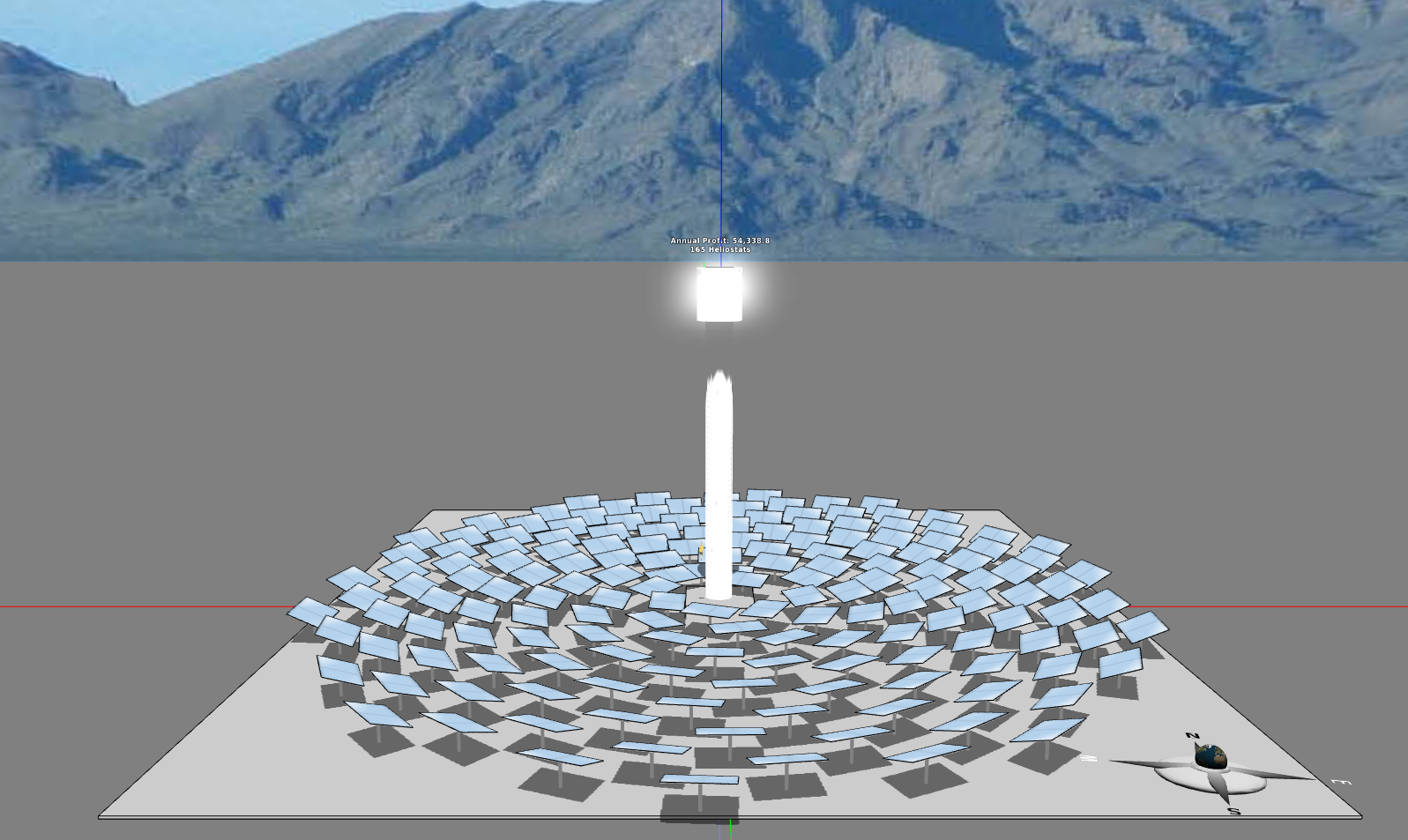

| Fig. 2: Sample student work presented in the paper |

1) System integration that facilitates formative feedback: Based on fundamental principles in science, the modeling and simulation capabilities seamlessly integrated within CAD tools can be used to analyze the function of a structure being designed and evaluate the quality of a design choice within a single piece of software (Figure 1). This differs dramatically from the conventional workflow through complicated tool chaining of solid modeling tools, pre-processors, solvers, and post-processors that requires users to master quite a variety of tools for performing different tasks or tackling different problems in order to design a virtual prototype successfully. Although the needs for many tools and even collaborators with different specialties can be addressed in the workplace using sophisticated methodologies such as 4D CAD that incorporate time or schedule-related information into a design process, it is hardly possible to orchestrate such complex operations in schools. In education, cumbersome tool switching ought to be eliminated — whenever and wherever possible and appropriate — to simplify the design process, reduce cognitive load, and shorten the time for getting formative feedback about a design idea. Being able to get rapid feedback about an idea enables students to learn about the meaning of a design parameter and its connections to others quickly by making frequent inquiries about it within the software. The accelerated feedback loop can spur iterative cycles at all levels of engineering design, which are fundamental to design ideation, exploration, and optimization. We have reported strong classroom evidence that this kind of integrated design environment can narrow the so-called “design-science gap,” empowering students to learn science through design and, in turn, apply science to design.

To read more about this paper, click here to go to the publisher's website.